Optimize material provision

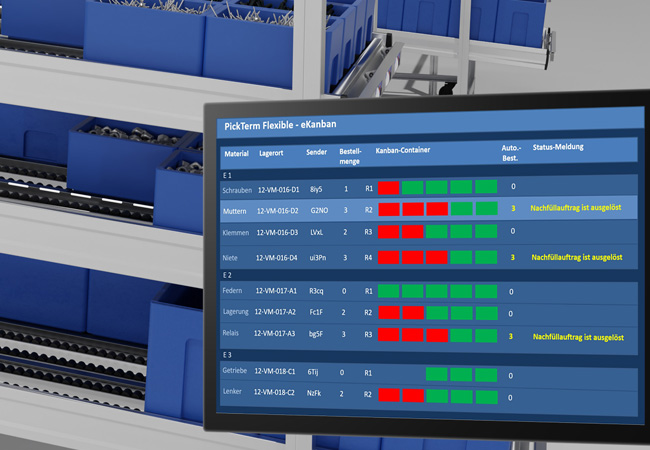

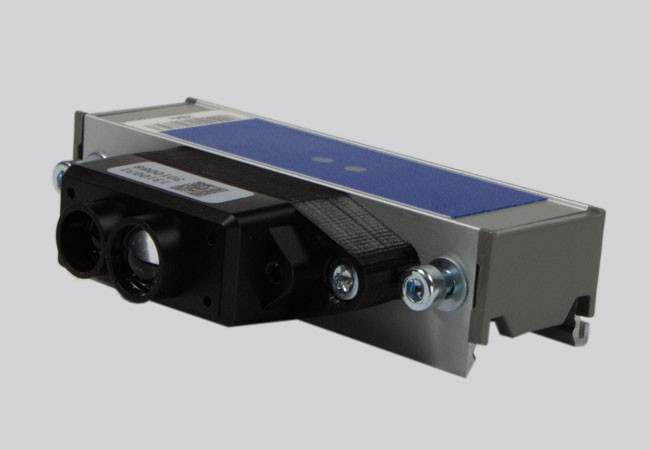

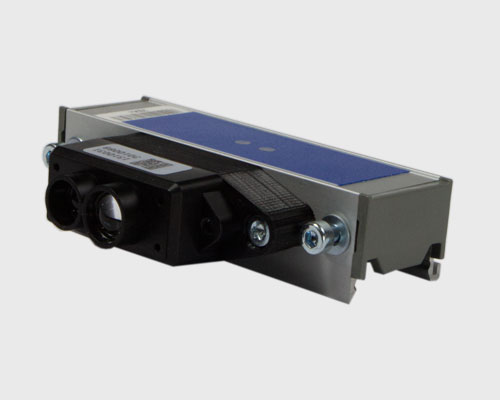

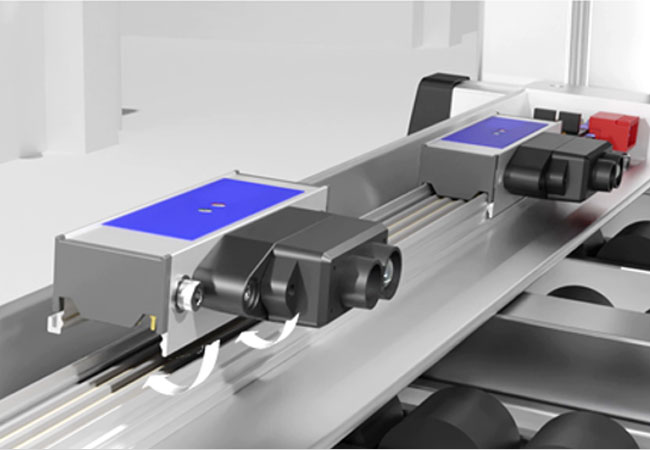

« SEKAN » e-Kanban system ensures the supply of materials to mounting and workstations. For this purpose, the E-Kanban shelf is equipped with a «SEKAN» control module for each roll flow rack. A high-performance sensor in the module continuously monitors the container fill level in the shelf. If the number of containers falls below a defined minimum, the system automatically reports the need for material replenishment to the ERP system. This reliably eliminates downtime due to a lack of material at the assembly station.

In contrast to a classic, card-based Kanban system, in which replenishment requests are made manually, the «SEKAN system» automatically monitors material replenishment.

Digital real-time level detection

The current container level is recorded in real time in the system. Using easy-to-use software, minimum levels, replenishment order quantities, replenishment request intervals, etc. can be easily configured and electronic replenishment requests generated.

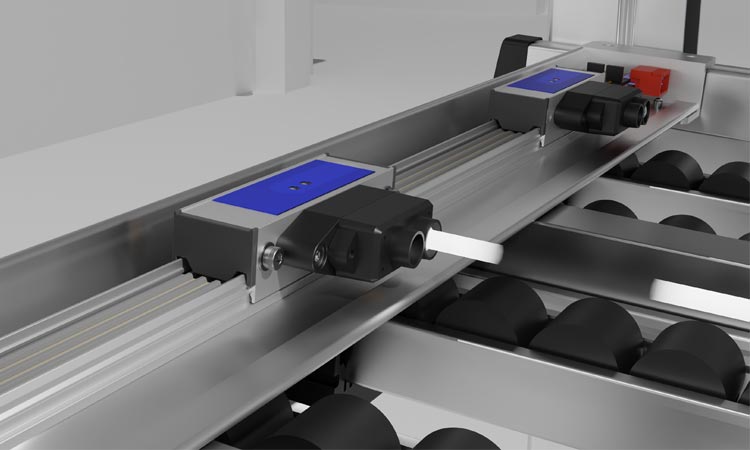

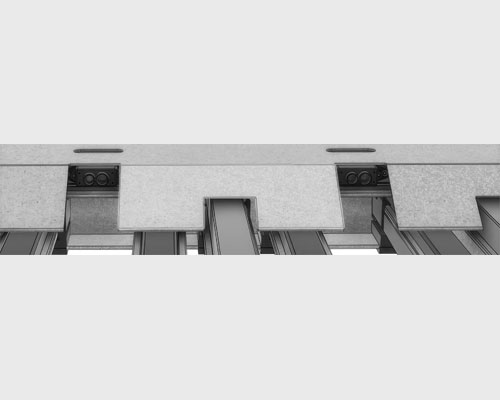

Easy mounting

Thanks to the proven KBS Snap-On technology, the SEKAN control module can be easily mounted and dismounted by clipping onto the base profile.

The advantages at a glance

✓ Digitization of processes through electronic recording

✓ Automatic real-time reporting of requirements

✓ Material replenishment is triggered automatically

✓ Only one sensor required per flow rack channel, for reliable level monitoring up to 4 meters shelf depth

✓ No cable routing, no battery or radio problems

Application

✓ Automatic real-time demand notification

✓ Support for the refill process at mounting and production stations

The system can be used for all common small load carrier sizes and standard flow rack shelf types, also in combination with a pick-to-light or put-to-light system from KBS.

KBS supports you in planning and implementation.

Simply pick up the phone and dial +49 (0)761 45 255-50 or use our contact form.